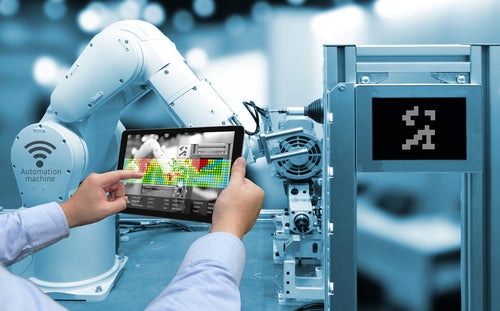

Concept: Engineers at Tennessee’s Oak Ridge National Laboratory have created a robotic disassembly system for old electric car battery packs to recover and reuse essential parts safely and effectively while decreasing hazardous waste. The robots can speed up disassembly while also making the process safer for workers and increasing throughput.

Nature of Disruption: The automated system, which ORNL engineers first developed to extract rare-earth magnets from obsolete hard drives, can disassemble even a charged battery. It can be quickly reconfigured to any sort of battery stack, and bolts and other housing can be quickly removed regardless of the remaining charge. The automated system can deconstruct the batteries down to the cell level, isolating various components such as rare earth magnets, copper, steel, and intact power electronics for recoveries. Individual battery modules can also be retrieved and reconditioned for use in energy storage systems.

Outlook: Only a tiny fraction of old batteries from electric vehicles are recycled today, and the bulk of recycling processes are manual. Whether a recycler simply wants to get through the outer housing to access batteries and replace worn components or wants to completely recycle battery stacks for recovery of cobalt, lithium, metal foils, and other materials, human operators must discharge used batteries in an exacting, time-consuming process before manually breaking them down. Human workers are exposed to hazardous compounds contained inside the batteries, as well as high power levels reaching 900 volts in some modern automobiles. However, the growth of ORNL engineers should be able to address these issues. Building up the robotic disassembly system to handle commercial amounts of used batteries might be the next stage. The researchers will also look at using the same type of disassembly system to dismantle electric vehicle drivetrains, which include valuable materials as well.